[ad_1]

The final two years have resulted in lots of modifications in each financial sector throughout the globe. That is very true for the manufacturing trade.

Most of the modifications had already been applied earlier than the beginning of the pandemic. Due to the pandemic, many of those are getting used to nice impact. These modifications have been kicked into excessive gear on account of components similar to instability within the provide chain, excessive demand for merchandise and altering buyer wants.

Inexperienced Traits to Look ahead to in 2022

1. Sensible digital thread

Massive producers have adopted IoT and IIoT to kickstart good manufacturing practices. These ‘digital threads’ play a key position in enhancing operational efficiencies, enhance product high quality and in flip model loyalty. Corporations are actually soliciting buyer inputs to reinforce buyer expertise with improvements and design modifications recommended by finish customers. Creating complete digital threads is not going to solely lead to inexperienced manufacturing practices however high quality merchandise as nicely. That is attainable because of safe digital platform connectivity.

2. Sustainability

Producers are additionally paying shut consideration to sustainability as nicely. Sustainability by way of environmental, social and governance insurance policies are now not simply watchwords. Corporations are investing in scalable applied sciences to enhance their manufacturing course of to cut back useful resource use whereas producing much less waste.

3. Extra onshore manufacturing

To save lots of prices, sourcing provides for manufacturing was outsourced to China and different nations. The pandemic has disrupted the provision chain and there’s no clear concept when the provision chain can be reset to the pre-pandemic degree. Utilizing provides made in-country will create extra jobs and scale back dependence on international sources whereas decreasing delivery prices. That is going to take priority in 2022.

4. Shifting focus from B2B format to B2C

Producers are actually focusing extra on B2C to supply the top buyer decrease priced items and to keep up model management. Producers have plenty of components to give attention to with buyer expertise high quality in thoughts.

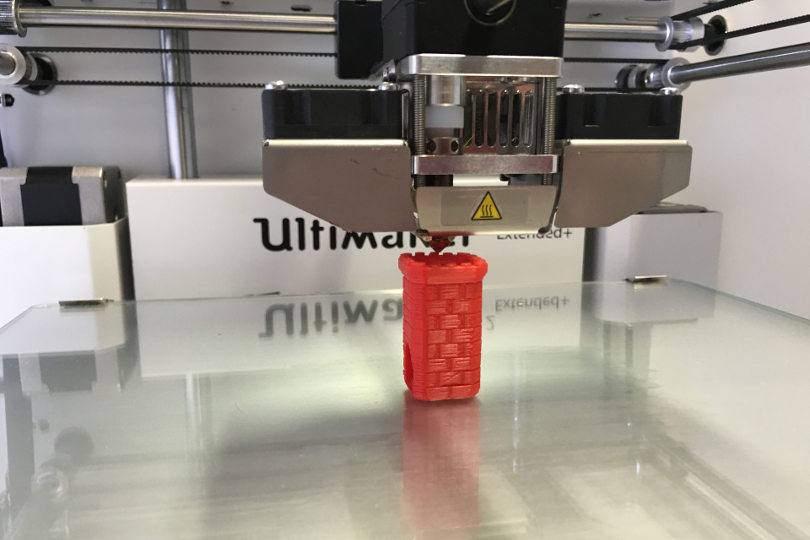

5. 3D Printing

Additionally known as additive manufacturing, 3D printing goes to be a giant factor in 2022. Among the advantages provided by this methodology are freedom to design, personalized merchandise and merchandise which carry out higher. Any such manufacturing promotes reasonably priced costs, sustainable course of and most vital of all, a shorter time to market. This course of is being actively used within the automotive and aerospace sectors.

6. Elevated use of automation

Automation has been in use for some time in a number of industries with PID controllers and PLCs. Wit the supply of quick computer systems and plenty of specialised software program packages, automation has stepped in to fill the void from employee shortages. Automated processes are actually in use not simply on the manufacturing facility flooring but additionally within the again workplace. Know-how and good machines are serving to with good determination making, product high quality and consistency.

7. Predictive upkeep

Know-how and automation are once more filling a niche and eliminating guesswork. Predictive upkeep packages monitor points and inform managers of issues within the manufacturing course of. Scheduled upkeep of equipment and components substitute can also be executed so that there’s little or no downtime. This ends in main prices financial savings which may then be handed on to the top consumer. Digital transformation is the way in which to implement this and different such packages.

8. Office expertise

The adoption of automation and different applied sciences in manufacturing signifies that the workforce should be technologically competent. Tech heavy industries like automotive and aerospace will want entry to a expertise pool which is acquainted with present practices. Many firms are working with vocational faculties in order that they’ve the best folks on the job.

Conclusion

A lot of the change in manufacturing is pushed by shopper enter nowadays. Finish customers need to know the way their gadgets have been manufactured and what supplies have been used. With a spike in vitality and uncooked materials prices, firms should additionally take care of environmental and different rules.

Shoppers are driving the change in the direction of sustainability and firms are taking their social accountability significantly. Happily, know-how helps to make loads of these choices and modifications attainable. Producers are keenly conscious of the connection between their model picture, manufacturing practices and earnings.

Entry to applied sciences like AI, robotics and blockchain will essentially shift the way in which merchandise are made.

[ad_2]

Source link